|

Étrave pour pick-up Lame biaise pour pick-up Chasse-neige extensible pour pick-up Étrave pour UTV Lame biaise pour UTV Étrave pour tracteur Lame biaise tracteur Chasse-neige extensible pour tracteur Chasse-neige pour camion HTrack™ |

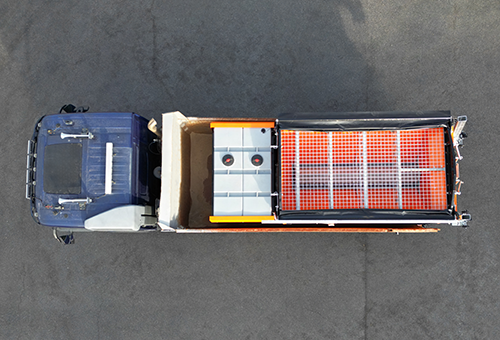

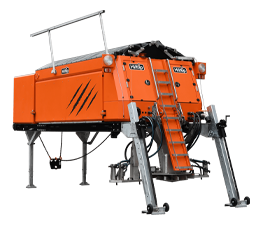

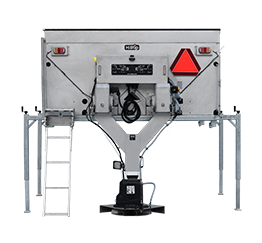

Saleuse à hayon Saleuse en acier inoxydable Saleuse combiné pour pick-up Saleuse pour tracteurs Saleuse combiné pour tracteur Saleuse combiné pour camion Saleuse combiné pour camion Saleuse Combinée pour Camions Saleuse à double compartiment pour camion Saleuses tractées IceStriker™ Saleuse godet |

Saumureuse HFE pour camion Saumureuse pour pick-up Saumureuse pour tracteur & UTV Station de fabrication de saumure SprayStriker™ Sprayer SprayStriker™ M-series SprayStriker™ Cannon Épandeur d'engrais en acier |

Balai poussoir Balai rotatif Balai rotatif pour camion Nettoyeur haute pression sur remorque Nettoyeur haute pression Nettoyeur haute pression hydraulique Dispositif de désherbage                                     |