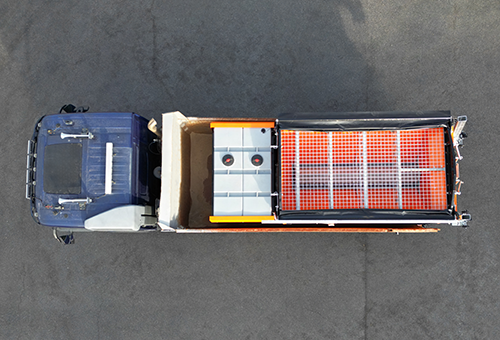

IceStriker™ LION 6-12 m³ Highway Combi Spreader for Trucks.

The Hilltip IceStriker™ LION 6–12 is a durable stainless steel combination truck spreader, available with either a hydraulic or 24V/48V electric drive. With a dry material capacity of 6 to 12 m³ it is ideal for highway applications. Easily operated through the StrikeSmart™ controller, the truck spreader comes standard with GPS speed control and the HTrack™ tracking system. Built to meet the EN 15597-2:2019 standard, the IceStriker™ LION ensures high-quality and efficient highway road maintenance.

Optionally, StrikeSmart™ Plus and TempStriker™ provide weather forecast data along with real-time air, road, and dew point temperatures. The control system automatically suggests the optimal spread rate for the driver, ensuring world-class ice control performance and maximum road safety.

The IceStriker™ LION truck-mounted spreader is versatile and can be easily converted into a complete liquid de-icing spreader or a pre-wet combi salt spreader. It can be equipped with a dual spray bar offering a working width of 2 to 14 meters. The spreader features lateral liquid tanks with a capacity of 2000 to 3000 liters and can be extended with 1 to 4 additional front-mounted liquid tanks, each with a capacity of 1250 liters.

The IceStriker™ LION truck spreader is compatible with our HTrack™ tracking software. You can track and manage all of your spreading devices and snowplows online on your computer, tablet or smartphone. The program shows treatment route and spreading details on the map in real-time or between specific time intervals. Spreading route details such as speed, GPS location and material used can be summarized and generated as PDF reports.

The StrikeSmart™ controller lets you customize your spreading session according to your current situation. Automatic GPS-speedcontrol adjusts the amount of spreading material (g/m²) according to your vehicle speed, while manual mode lets you insert a fixed auger speed. The controller additionally collects and saves essential data to an USB memory, allowing you to generate spreading reports. The controller also makes it easy to turn on functions, like vibrator, beacon and work light, from inside the cabin.

The truck spreader is available with either a hydraulic drive or a 24V/48V electric drive.

Automatic vibrator prevents material from clogging.

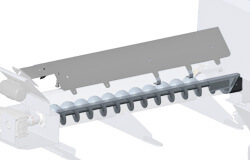

Inverted-V helps reduce heavy start-up loads on the auger/conveyor. All in stainless steel.

Choose the feed mechanism you prefer: chain conveyor (500 mm width) or dual auger.

Work light can be activated from the standard StrikeSmart™ controller.

Beacon light can be activated from the standard StrikeSmart™ controller.

Strobe lights for enhanced visibility and safety.

HTrack™ 2-way online tracking & control system.

StrikeSmart™ Plus and TempStriker™ provide weather forecast data along with real-time air, road, and dew point temperatures.

The flip-down ladder provides safe and easy access for maintenance and inspection.

Dual liquid spray bar – working width 2-14 m.

The two-piece tarp mechanism is easy to open and close.

Additional 1250 L front-mounted liquid tanks (1-4 pcs) and legstand frame extension.

Rear and indicator lights for enhanced visibility and safety.

Leg stand for practical storing and easier removal and installation.

End of material alarm sensor on spinner.

Spreader specifications and dimensions

SPREADER SPECIFICATIONS

| MODEL | LION 6 | LION 7 | LION 8 | LION 9 | LION 10 | LION 12 |

|---|---|---|---|---|---|---|

| Hopper capacity, rounded | 6 m³ | 7 m³ | 8 m³ | 9 m³ | 10 m³ | 12 m³ |

| Liquid capacity lateral tanks | 2000 L | 2000 L | 2500 L | 3000 L | 3000 L | 3000 L |

| Liquid capacity with added front tanks | 3250-5750 L | 3250-5750 L | 3750-6250 L | 4250-6750 L | 4250-6750 L | 4250-6750 L |

| Type of drive | Electric 24V/48V or hydraulic | |||||

| Length on truck bed (without front tanks) | 360 cm | 360 cm | 430 cm | 500 cm | 500 cm | 500 cm |

| Total length | 450 cm | 450 cm | 520 cm | 590 cm | 590 cm | 590 cm |

| Hopper width | 213 cm | |||||

| Hopper height | 141 cm | 156 cm | 141 cm | 141 cm | 156 cm | 176 cm |

| Feed mechanism | Chain conveyor (500 mm width) or dual auger | |||||

| Spreading disc diameter | Ø650 mm | |||||

| Spreading width | 3-14 m | |||||

| Material of construction | Stainless steel | |||||

| Empty weight approx. | 1680 kg | 1740 kg | 2055 kg | 2230 kg | 2300 kg | 2400 kg |

| Mounting system | Fixed / Leg stand / Hook lift frame | |||||

LIQUID SYSTEM (optional)

| MODEL | LION 6-7 | LION 8 | LION 9-12 |

|---|---|---|---|

| Pre-wet, Max spray volume | 200 L/min | 200 L/min | 200 L/min |

| Spraybar, Max spray volume | 400 L/min | 400 L/min | 400 L/min |

| Pre-wet, Spraying width | 2-14 m (together with spreading material) | ||

| Spraybar, Spraying width | 2-14 m | 2-14 m | 2-14 m |

| Liquid tank capacity – lateral tanks only | 2000 L | 2500 L | 3000 L |

| Liquid tank capacity – with front mounted tanks | 2000-5750 L | 2500-6250 L | 3000-6750 L |

| Spraying material | Anti- and de-icing liquids, water. ** | ||

** Do not use flammable or petroleum liquids for the liquid system

See how much you can save by reducing material costs with a liquid system

kg/year *

€/kg *

You can save in material costs annually

* Calculations based on the following application rates: Dry salt 30g/m2, Pre-Wet 17g/m2, Brine 35ml/m2. With a Pre-Wet system the application rate is significantly lower, as the pre-wetted salt bonds to the ground and immediately start breaking up the ice.

Get more out of your spreader by reading related articles and manuals