Pursuing energy efficiency in mechanical systems is a crucial aspect of modern snow-clearing machines, particularly in electric auger drive feed systems. Hilltip has taken significant steps in addressing these challenges by implementing innovative designs and advanced technologies, resulting in environmentally conscious and cost-effective snow management solutions.

The Role of the Auger

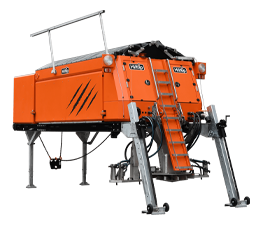

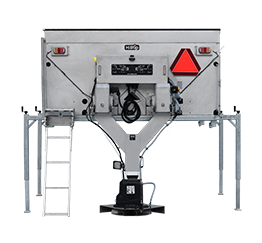

The primary function of the auger in a sand and salt spreader is to move the material from the storage hopper to the distribution mechanism. The auger is essentially a helical screw blade that, when rotated, transports the sand or salt along its length. The auger also offers several operational advantages, such as precise control of the dispensing rate of the material, effective breakup of clumps to maintain consistent flow, and ensuring a uniform distribution of the sand or salt over the treated surface.

Overcoming Energy Efficiency Challenges

Making an electric auger drive feed system energy efficient presents several challenges due to the inherent characteristics of auger systems and the nature of electric drives. Let’s take a look at some of these challenges:

- Friction and Wear: Auger systems typically involve significant friction as they rotate within a housing or tube. This friction requires additional energy to overcome, especially when the auger is heavily loaded or if the material being moved is particularly abrasive or sticky. Over time, wear can increase friction further, reducing efficiency.

Hilltip has effectively addressed this by using an auger with a variable pitch design, optimizing spiral spacing to minimize resistance and enhance material transfer efficiency. Additionally, stainless steel, renowned for its smoothness, further reduces friction and wear. This results in more consistent, long-term performance and improved system energy efficiency. - Torque Requirements: Augers often require high torque at low speeds to move heavy or dense materials. Electric motors can be less efficient at generating high torque, especially at lower speeds. This can necessitate using gearboxes or other mechanical systems to increase torque, adding complexity and potential energy losses. Hilltip’s auger drive feed systems are designed to minimize energy losses. They achieve this through a high-efficiency helical gearbox with an impressive 98% efficiency rate. The efficiency of the gearbox is due to the rolling contact found in helical gears. This reduces friction compared to commonly used worm gears in the snow and ice industry, which have sliding contact. Worm gearboxes with a ratio of 1:25 have an efficiency of 80% or less, and Hilltip’s innovative auger drive system results in a minimum of 18% higher energy efficiency.

- Variable Load Conditions: The load on an auger can vary significantly based on the type of material (rough or fine) being moved and the volume of material in the system. Electric drives need to adapt to these changing conditions efficiently, which can be challenging.

Hilltip’s auger systems have been designed to handle variable loads effectively. The systems incorporate baffles and a fixed inverted V to ensure optimal performance. Baffles act as barriers within the hopper to control material flow and prevent overloading by distributing the load evenly along the auger. The inverted V complements this by directing the material to the sides, avoiding accumulation at the center. Together, these features ensure a consistent load, enhancing efficiency and performance, regardless of material type or volume. - Control System Complexity: Efficient operation of an electric auger drive system may require sophisticated control systems that can adjust motor speed, torque, and power draw in response to changing conditions.

Hilltip addresses this by employing a closed-loop system in their auger drives. This system continuously monitors and adjusts the auger’s real-time performance, ensuring optimal efficiency and response to varying material loads and conditions. The benefits of a closed-loop system in an auger setup include enhanced precision in control, reduced energy wastage, and improved overall system reliability.

Moreover, Hilltip’s auger systems are enhanced with the StrikeSmart control system. Operators can adjust settings and get immediate alerts for issues like overload or inefficiency, simplifying operation and a diagnostic view aiding in proactive maintenance, thereby improving the system’s efficiency and durability. - Start-up Energy Demand: Starting an auger system, particularly when it is fully loaded, can require a significant amount of energy.Electric motors draw a lot of power during start-up, which can be inefficient, especially if start-ups are frequent.

The even load distribution achieved by using baffles allows the electric motor to start with less power, as it faces less resistance from compacted or uneven material. Consequently, this reduces the energy surge at start-up and decreases strain on the motor and gearbox, enhancing operational efficiency and extending equipment lifespan.

Hilltip’s Innovative Solutions

Hilltip has effectively overcome energy efficiency challenges in electric auger drive systems by employing innovative strategies that significantly lower start-up energy demand and improve overall system efficiency and longevity, showcasing Hilltip’s commitment to innovative and sustainable solutions in auger technology.

Discover more about how Hilltip is revolutionizing auger systems and explore the range of efficient, high-quality products on our website.