This article is written by Paddy Hastie, Winter Equipment Manager at Peacock Salt and a member of the National Winter Service Research Group‘s (NWSRG) Technical Advisory Group.

Peacock Salt recently undertook a study to compare the salt saving recovered by a number of UK Gritting Contractors when they switched from a leading brand salt spreader, to the Hilltip IceStriker 850.

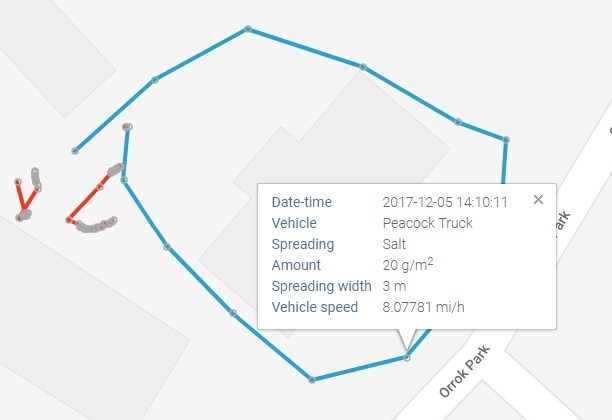

The Hilltip IceStriker 850 uses GPS technology to allow the driver to apply salt using a g/m2 control. The system ensures the amount of salt is consistent with that target regardless of changes in the vehicle speed.The effect is a higher control over salt distribution and protection against over-salting.

The leading brand spreader’s technology is commonplace, with an auger and spinner control. Users can follow a calibration method at each site with the aim of putting down an appropriate amount of salt. Often this can lead to covering the ground in salt without adhering to any particular guidelines. There can be salt wasted and a high cost incurred, as a result.

Peacock Salt compared data over two winter seasons, one year with the leading brand spreader and one season with the Hilltip IceStriker 850. The comparison used the same region of the country and winters with similar weather pattern. It also accounted for the number of site visits and worked out a weight per site visit. Both spreaders held a similar weight of salt.

It was found that sites using the Hilltip IceStriker 850 used 33% less salt.

Customer satisfaction remained consistent over the period. No detrimental effect was noted on claims from slips, trips and falls. These spreaders also used Hilltip HTrack which helped one Contractor to more than halve the time taken to resolve any claims which did arise.