As the world shifts towards sustainable solutions, the use of electric vehicles (EVs) for snow and ice removal is emerging as an innovative approach. However, integrating snow and ice removal equipment with EVs presents unique challenges. These challenges stem from the specific characteristics of EVs and the rigorous demands of snow removal tasks. Understanding these challenges and finding effective solutions is crucial for the successful adoption of electric snow removal methods. Let’s explore the key challenges and how Hilltip has developed strategies to overcome them.

Battery Performance in Cold Weather

In low temperatures, typical of snow removal operations, EV battery efficiency can decrease, affecting the vehicle’s range and power. This impacts the ability to perform extended or intensive snow removal tasks.

Hilltip’s Solution: Hilltip addresses this by designing lightweight snow removal equipment and with energy-saving features to reduce energy demand on EVs. They employ advanced insulation and smart technology to optimize operation, minimizing energy wastage and maximizing efficiency, thus easing the strain on the vehicle’s battery in cold conditions.

Power and Towing Capacity

Traditional, heavy snow removal equipment may surpass the power and towing capabilities of some EVs. Despite ongoing advancements, many EVs still don’t match the power and torque of diesel vehicles, crucial for effective plowing and hauling.

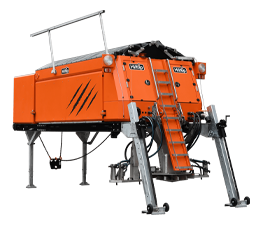

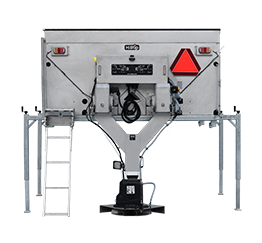

Hilltip’s Solution: Hilltip has developed not only lightweight but also highly efficient equipment, with innovative designs for even weight distribution, a patent pending energy efficiency pump system for de-icing sprayers and improved equipment aerodynamics for snow plows. This reduces overall power requirements. Hilltip also collaborates with EV manufacturers to ensure compatibility and enhance the power and towing capacity of EVs equipped with their snow removal tools.

Range Anxiety

Snow removal requires vehicles to operate for long periods over extensive areas. The limited range of some EVs, especially when loaded with snow clearing equipment, necessitates careful operation planning to avoid frequent recharging.

Hilltip’s Solution: Hilltip’s equipment includes advanced control systems for efficient energy management. This allows operators to conserve battery life through precise control over functions like plowing depth and salt spreading rate. Strategic route planning is also recommended to improve efficiency and reduce recharging needs; here is where the Hilltip fleet management & control system HTRACK™ comes in handy.

Vehicle Weight and Balance

Adding snow removal equipment like plows and salt spreaders can significantly change an EV’s weight distribution and balance, impacting handling and performance.

Hilltip’s Solution: Hilltip’s equipment is designed to maintain the balance and handling of electric vehicles. They use modular designs on the salt spreaders and sprayers for even weight distribution across the vehicle, minimizing impact on performance and handling. Hilltip also offers customizable solutions, adapting their snow plow equipment to a variety of electric vehicle models while considering their specific weight and balance properties. The most common EV vehicles that are equipped with Hilltip snow plows and salt spreaders are brands like GOUPIL, EVERUM, ALKE and MUP Technologies, which fall into the category of special municipial vehicles. The more traditional vehicle manufacturers are Ford Lightning, Ford Transit trucks as well as FUSO, MAXXUS and FOTON trucks that are equipped with Hilltip snow and ice removal equipment.

Embrace the Future with Hilltip

Hilltip has proactively tackled these challenges through innovative design, strategic collaborations, and smart technology integration, enhancing the efficiency and effectiveness of snow removal operations with electric vehicles.

Explore our wide range of snow and ice removal equipment today, and discover how they can revolutionize your winter maintenance strategies!